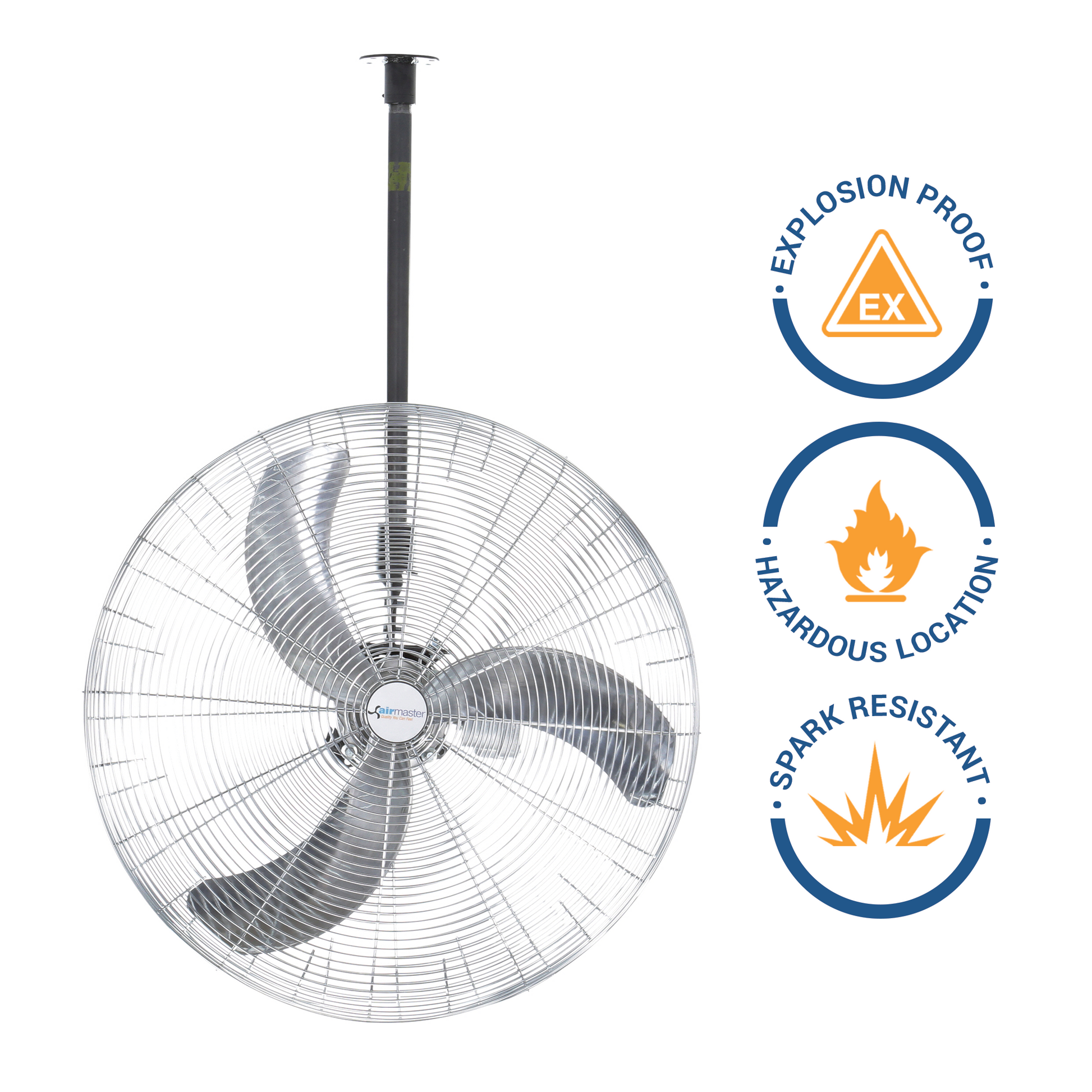

Heavy-Duty, Hazardous Location Air Circulator

SKU: 20321

Couldn't load pickup availability

Description

Spark Resistant, Explosion Proof Motors for Hazardous Locations

Airmaster's Premium Flagship Line

Backed by our Limited Lifetime Warranty*

Working in high-risk environments leaves no room for error. The Airmaster Heavy-Duty Hazardous Location Air Circulator ensures safe air movement, even in chemical plants, refineries, or other hazardous environments. Its robust design meets strict safety standards while maintaining effective airflow for people and equipment.

- Certified for Class I and Class II hazardous locations to protect your team.

- Part of our flagship line featuring our proprietary die-cast aluminum, ultra-quiet propeller

- Maintains cooling in high-risk, high-heat industrial areas.

- Heavy-duty construction ensures continuous operation without failure.

Protect your crew and your productivity. This fan delivers airflow where it matters, without compromising safety or reliability.

Built for environments with explosive gas, vapors, or dust—including oil refineries, welding shops, and paint operations—this non-oscillating fan combines safety and durability with OSHA-approved guards and spark-resistant construction.

Features:

- 115/230 V, 1/4 HP, 1 Phase or 230/460 V, 1/4 HP, 3 Phase Motor

- Single Speed, Ball Bearing Motors

- Energy Efficient - Lowest Watts Per CFM, Ultra Quiet Die Cast Aluminum Airfoil Propeller

- Excellent for Hazardous Location Applications such as: Oil Refineries, Painting Operations, Welding Shops, Chemical Plants, Grain Elevators, Coal Mines, Grain Mills, Battery Charging Areas, Chemical Storage, Paint Storage, Dry Cleaners, Laboratory Hoods, Feed Mills, Flour Mills, and Electroplating Operations

- Guards meet OSHA Standards

- Assembled in the USA

- Explosion Proof Motor for Class 1, Group D & Class II, Groups E, F & G

Motor, Specified Mounting, Propeller, and Guard are shipped in a single container.

Note: All fans must be installed in accordance with all applicable national, state, and local electrical and mechanical codes. For further information, please contact Airmaster Engineering.

- Free Shipping in the USA

- Lifetime Warranty*

- Assembled in the USA

Need to place a custom or large order? Check our network of Trusted Distributors to find one nearest to you.

Secure Checkout with

Notify me